Polyvinyl chloride, better known as PVC or vinyl, is a plastic so versatile, it has become completely pervasive in modern society. The list of products made from PVC is exhaustive, ranging from phonograph records to drainage and potable piping, water bottles, cling film, credit cards and toys. More uses include window frames, rain gutters, wall panelling, doors, wallpapers, flooring, garden furniture, binders and even pens. Even imitation leather is made of it. In fact, it's hard to turn anywhere without seeing some form of this plastic. PVC was accidentally synthesized in 1872 by German chemist Eugen Baumann. PVC is a thermoplastic material and about 57% of the mass of PVC is chlorine

Its toughness, strength, ease of blending, ease of processing, flame resistant and fire prevention properties make it appropriate for several applications. PVC is compatible with other additives that can make PVC clear or colored, rigid or flexible, etc. It also has excellent electrical insulation properties which makes it ideal to be use in cables. PVC has strength and resistant to bad weather conditions (i.e. it does not corrode and is very durable), appropriate to be used as a construction material, Resistant to grease, oil and chemicals and thus is chemically stable and does not de-polymerize. Due to its various properties and ease of use, the 2022 FIFA World Cup Qatar Showcase Stadium has been designed to use super reflective, triangulated PVC fabric to create a zero carbon, sustainable stadium providing comfortable playing conditions.

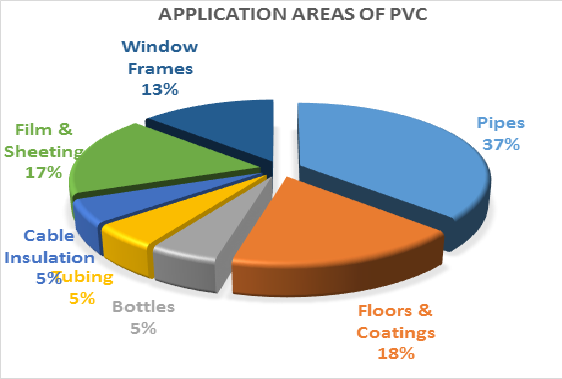

Due to PVC properties, as described above, around 50% of PVC (or vinyl) manufactured is used in construction replacing other materials such as wood or glass. Cheap, resistant, good weather ability, ect. PVC is strong, lightweight, durable and versatile. These characteristics make it ideal for window profiles. PVC's inherent flame retardant and excellent electrical insulation properties make it ideal for cabling applications. It can be used for flooring, windows and door frames and shutters, water and waste pipes, electrical applications such as cable and wire insulation materials, architectural glazing systems, wallpaper, etc.

Over the past few years, over one hundred and forty two thousand square metres of PVC fabric has been used to create new sporting venues in London alone. In celebration of the role that PVC can play at sporting events, thhe diverse range of PVC product applications for performance sports surfaces, sports equipment and clothing are also used.

PVC has been widely used for surgery, pharmaceuticals, drug delivery and medical packaging. Some products include blood bags, medical containers, fluid bags, tubing, heart and lung bypass sets, masks, gloves, bottles and jars, drainage systems, ducting, etc. The reasons to use it in the medical sector is its safety and chemical stability and bio-compatibility, chemical resistant and low cost. In addition, it is usable inside the body and easy to be sterilized.

Flexible PVC flooring is inexpensive and used in a variety of buildings covering the home, hospitals, offices, schools, etc. Complex and 3D designs are possible due to the prints that can be created which are then protected by a clear wear layer. A middle vinyl foam layer also gives a comfortable and safe feel. The smooth, tough surface of the upper wear layer prevents the buildup of dirt, which prevents microbes from breeding in areas that need to be kept sterile, such as hospitals and clinics.

PVC has become widely used in clothing, to either create a leather-like material or at times simply for the effect of PVC. PVC clothing is common in Goth, Punk, clothing fetish and alternative fashions. PVC is less expensive than rubber, leather, and latex which it is therefore used to simulate. PVC fabric is water-resistant so is used in coats, skiing equipment, shoes, jackets, aprons, and bags.

Roughly half of the world's polyvinyl chloride resin manufactured annually is used for producing pipes for municipal and industrial applications. Its light weight, low cost, and low maintenance make it attractive. However, it must be carefully installed and bedded to ensure longitudinal cracking and overbelling does not occur. Additionally, PVC pipes can be fused together using various solvent cements, or heat-fused (butt-fusion process, similar to joining HDPE pipe), creating permanent joints that are virtually impervious to leakage.

Plastic is increasingly an integral part of modern cars. Any brand would be challenged to manufacture a modern car which doesn’t contain some plastic elements. In fact, the European Council of Vinyl Manufacturers (ECVM) estimates that around 150kg of plastics are used within an average vehicle. Building today’s cars requires high performing materials, which help protect occupants, produce cheaper, cleaner and more energy efficient vehicles and last the life of the car, typically 10-15 years. Plastics, including soft PVC in particular, have played a very significant role in light-weighting and improving performance and efficiency. PVC is affordable, Cold temperature resistant, UV stable, durable, light weight and can be used in making Soft and scratch resistant skins for dashboards.

It is flexible, light, cost-effective, transparent, tough and safe. It has excellent organoleptic properties (does not affect the taste of the packaged food) PVC requires less fuel to manufacture and transport when compared with other packaging materials such as metal or glass, and protects against contamination by helping to prevent the spread of germs during manufacture, distribution and display, particularly in the form of cling film. This, combined with PVC's excellent oxygen and water barrier properties, prevents unnecessary wastage as it ensures food lasts longer.

PVC is commonly used as the insulation on electrical cables; PVC used for this purpose needs to be plasticized. Electricity is essential to our standard of living, a valuable and versatile servant — but it is also potentially lethal. PVC does not conduct electricity and is therefore used in a variety of applications where their insulating properties are needed. PVC is widely used to insulate electric wiring, while thermosets (which can withstand high temperatures) are used for switches, light fittings and handles. PVC is especially suited to housings for goods such as hairdryers, electric razors and food mixers as they protect the consumer from the risk of electric shock. PVC is also poor conductor of heat. To reduce the risk of burns, manufacturers have therefore made extensive use of PVC, introducing cool-touch toasters, deep-fat fryers and kettles. To further protect the consumer, PVC can be made fire resistant through the use of special flame retardant additives.

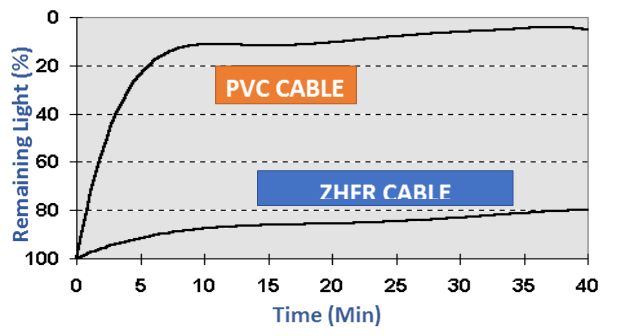

Zero Halogen Flame Retardant (ZHFR), Halogen free flame retardant (HFFR), low smoke zero halogen (LSOH), low smoke and fume (LSF) are all names associated with compounds that are finding increased use in the European, Asian and Middle Eastern markets.

Most network cables are insulated with polyethylene, PVC or thermoplastic polyurethane. In a fire, a chlorine-containing plastic material releases hydrogen chloride, a poisonous gas that forms hydrochloric acid when it comes in contact with water. Designated halogen-free cables, on the other hand, do not produce a dangerous gas/acid combination when exposed to flame

Low smoke zero halogen cable reduces the amount of toxic and corrosive gas emitted during combustion. This type of material is typically used in poorly ventilated areas such as aircraft, rail cars or ships. It is also used extensively in the railroad industry, wherever high voltage or track signal wires must be run into and through underground tunnel systems. This reduces the chance of toxic gasses accumulating in these areas should the wires be damaged by fire or a short circuit fault.

Low smoke zero halogen is becoming very popular and, in some cases, a requirement where the protection of people and equipment from toxic and corrosive gas is critical. ZHFR cabling is the safest choice for all applications in which smoke is likely to both build up and come into contact with people, since no harmful toxins are actually released. Low Smoke Zero Halogen cable also has the added benefit of complying with the European Union’s Restriction of Hazardous Substances (RoHS) directive and similar North American safety and environmental standards.

The clearest uses for ZHFR are confined spaces with large amounts of cables in close proximity to humans or sensitive electronic equipment. Submarines and ships are classic examples, which is why the military was one of the first adopters of ZHFR standards. Additionally, mass transit and central office facilities are common applications for ZHFR, and many telecommunication standards require ZHFR cables.

The use of ZHFR cables in Europe has been widespread since the 1980s. It has never achieved such widespread acceptance in the United States, primarily for cost reasons, but also because of performance concerns. Some of the cable designs used in Europe cannot pass U.S. test standards, and the high additive loading needed to pass the U.S. flame tests can lead to reduced physical properties if not done carefully.

Installation at lower temperatures can also be affected. Reduced flexibility due to the high additive loading in the materials can prevent cables from being installed in cold environments. The high mineral content can also result in fractures of the material if the installation is not done carefully. Research of the cracking behaviour of ZHFR has been done with the goal of improving performance .

Since the 1970s, the wire and cable industry has been using low-smoke, low-halogen materials in a number of applications. The objective was to create a wire and cable jacketing that was not only flame retardant but also did not generate dense, obscuring smoke and toxic or corrosive gases. Several notable fires over the years (such as the King’s Cross Fire that killed 32 people in London’s underground subway in 1987) increased the awareness of the role that wire and cable jacketing plays in a fire and contributed to a greater adoption of ZHFR cables. With an increase in the amount of cable found in residential, commercial and industrial applications in recent years, there is a greater fuel load in the event of a fire. Wire and cable manufacturers responded by developing materials that had a high resistance to fire while maintaining performance. Low-smoke, zero-halogen compounds proved to be a key materials group that delivered enhanced fire protection performance. Today, low-smoke, zero-halogen cables are being used in applications beyond the traditional transit, shipboard, military and other confined-space applications.